We are taking a step back here, but one of the first decisions we had to make was what kind of shell we would put on the back of the truck. You already know we decided on an aluminum frame and aluminum skin, but lots of ideas were considered and tossed before we came to that decision. We thought about reclaiming a box truck, which would have a ready made shell, but decided that it would be a pain to add the cab over, and probably wouldn’t be in great shape. We also looked at an ambulance back, which was great because it was already wired and plumbed, but it didn’t provide the space we needed for using the camper for more than weekends, and would have required a lot of modification for our cargo requirements. We considered getting a junked school bus and having the top attached to our flatbed, but decided it would be more trouble than it was worth, probably would be too heavy, and would most likely end up looking like the Frankenstein monster of campers. It was only after thinking through all of these options that we even decided to talk to Koops Tinsmith and get a quote for an aluminum shell, and we were pleasantly surprised that their quote was very reasonable.

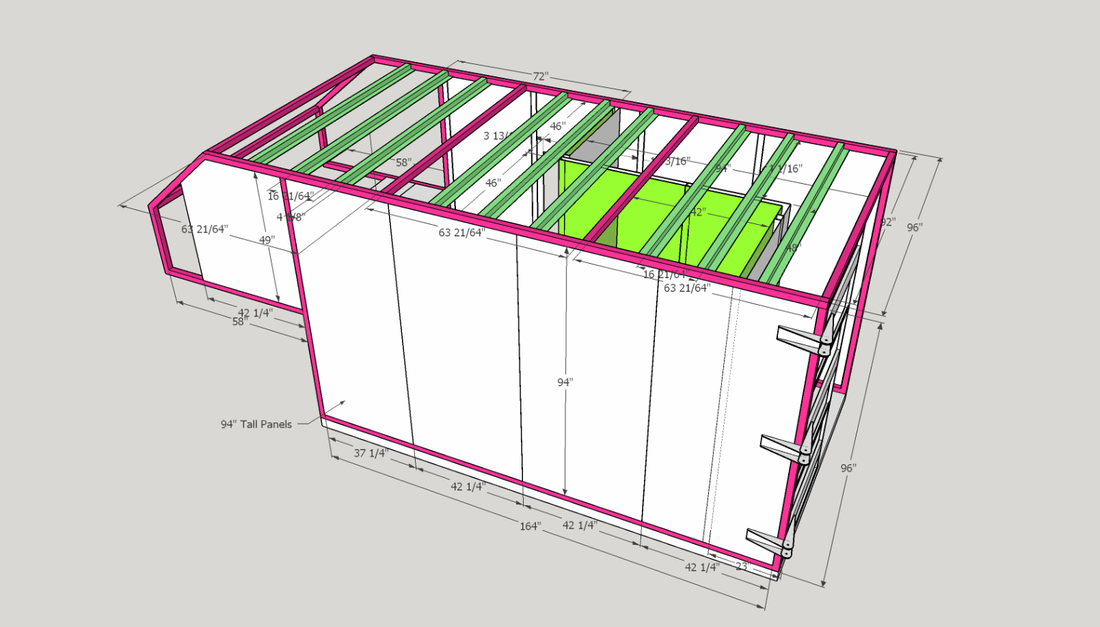

We already blogged about our basic requirements, and we had already put a lot of thought into that as we were making the decision about the shell. That made it easy to come up with a general sketch of what we wanted, and go to Koops to turn that into a CAD drawing that would not only give us a picture of what we were imagining, but also give Koops a good idea to make a estimate based on materials and the time they would take to build it. But, we still had a lot of decisions to make.

Our first decision was about the floor. While we bought the truck partly because of the flatbed, we’ve realized that this particular flatbed is quite heavy. We briefly thought about taking it off and having a lighter floor built as part of the camper build, but in the end decided to try to conserve weight elsewhere and keep the flatbed as we bought it. It’s very sturdy and well made, and will make a great base for whatever we put on top.

We then had to figure out how the walls, ceiling, and basic shell would be constructed. They need to be strong enough to not only support themselves, but also to support whatever needs to be attached to, and possibly hung from, them inside. They also need to be insulated, because we are planning on using the camper in a wide range of temperatures, and they to be able to keep the cool in when it’s hot, and the heat in when it’s cold. They need to accommodate windows and vents, as well as doors. We talked to Justin at Koops, and came up with a plan for an aluminum skin with 2” foam board insulation. We are still working out details on exact measurements, but we have a plan.

Our first decision was about the floor. While we bought the truck partly because of the flatbed, we’ve realized that this particular flatbed is quite heavy. We briefly thought about taking it off and having a lighter floor built as part of the camper build, but in the end decided to try to conserve weight elsewhere and keep the flatbed as we bought it. It’s very sturdy and well made, and will make a great base for whatever we put on top.

We then had to figure out how the walls, ceiling, and basic shell would be constructed. They need to be strong enough to not only support themselves, but also to support whatever needs to be attached to, and possibly hung from, them inside. They also need to be insulated, because we are planning on using the camper in a wide range of temperatures, and they to be able to keep the cool in when it’s hot, and the heat in when it’s cold. They need to accommodate windows and vents, as well as doors. We talked to Justin at Koops, and came up with a plan for an aluminum skin with 2” foam board insulation. We are still working out details on exact measurements, but we have a plan.

We also had to think about doors and windows. We thought about repurposing windows and doors from one of the many junked campers that exist in Belize as well as everywhere else, but decided that since we know exactly what we want, it would be more expensive but ultimately better quality and more satisfying for us if we bought new windows. We then thought about getting house-type windows custom made, but after talking to local window manufacturers, we determined that those windows are not meant to be installed on a moving, flexing wall and we would undoubtedly have no end of problems. So, Tom found a company that manufactures RV windows. We then had to decide if we wanted the more expensive custom windows, or stock sizes, and decided that since the stock sizes were so much less expensive, we could work our design around the windows. After determining what windows we wanted, Tom placed an order and had them shipped to Belize. He also ordered an RV door which will be used to access the living quarters.

Koops will build the rear doors, which will swing out and will be the entire back side of the structure. These doors will open into the cargo/utility area, which will be separated from the living quarters by an interior wall, which will also be insulated.

The roof became surprisingly complicated, because it has so many purposes beyond just being the top of the camper and keeping the weather out. It will have three vents whose placement is dictated by the inside design of the living space, but will also need to fit an array of solar panels, which is still to be determined. We’ve discussed putting a rail around the top, which would be useful both for tying down things we may carry on top, and for running wires for the electrical system, and possibly anchoring water lines if we rig up a solar water heater. And, if any space is left over, we may consider a roof top deck to be accessed from the escape hatch over the bed.

We are meeting with Justin at Koops tomorrow to iron out some of the finer details and to schedule dropping the truck off to start the build. We have a room full of windows and vents, as well as appliances we’ve already bought, and are waiting only for the living quarters door, which should arrive at the end of the week. It is starting to seem real!

We are meeting with Justin at Koops tomorrow to iron out some of the finer details and to schedule dropping the truck off to start the build. We have a room full of windows and vents, as well as appliances we’ve already bought, and are waiting only for the living quarters door, which should arrive at the end of the week. It is starting to seem real!