Our first decision was about the floor. While we bought the truck partly because of the flatbed, we’ve realized that this particular flatbed is quite heavy. We briefly thought about taking it off and having a lighter floor built as part of the camper build, but in the end decided to try to conserve weight elsewhere and keep the flatbed as we bought it. It’s very sturdy and well made, and will make a great base for whatever we put on top.

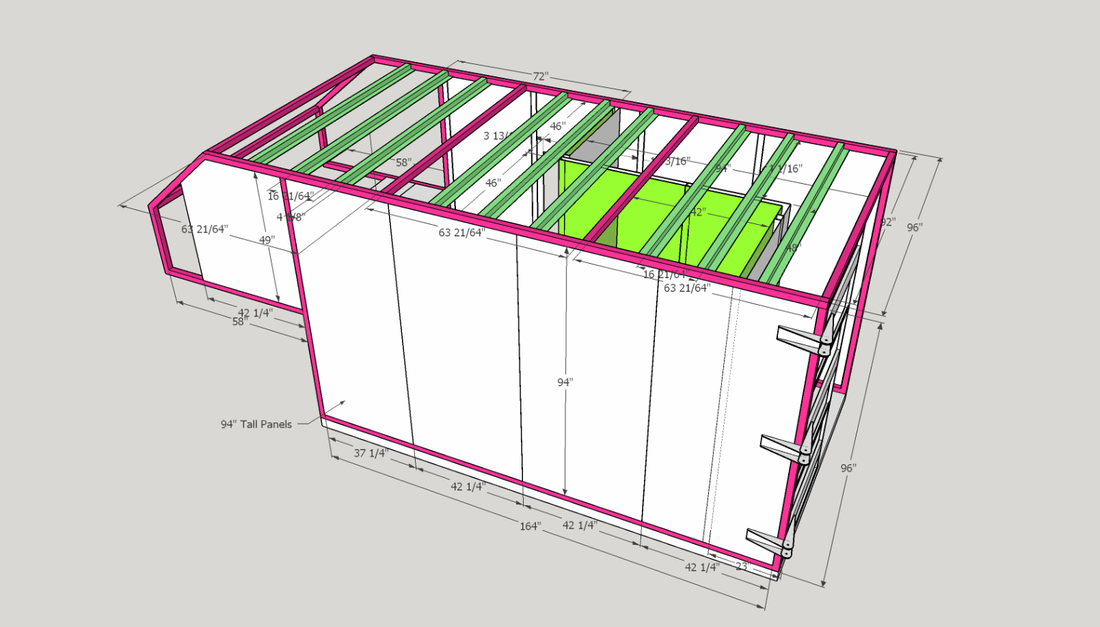

We then had to figure out how the walls, ceiling, and basic shell would be constructed. They need to be strong enough to not only support themselves, but also to support whatever needs to be attached to, and possibly hung from, them inside. They also need to be insulated, because we are planning on using the camper in a wide range of temperatures, and they to be able to keep the cool in when it’s hot, and the heat in when it’s cold. They need to accommodate windows and vents, as well as doors. We talked to Justin at Koops, and came up with a plan for an aluminum skin with 2” foam board insulation. We are still working out details on exact measurements, but we have a plan.

We are meeting with Justin at Koops tomorrow to iron out some of the finer details and to schedule dropping the truck off to start the build. We have a room full of windows and vents, as well as appliances we’ve already bought, and are waiting only for the living quarters door, which should arrive at the end of the week. It is starting to seem real!